The optimum interplay of individual components is very important for a brake system. The brake cylinders have a decisive role because they have to ensure the perfectly controlled force transmission in the brake system. BPW develops and manufactures its own brake cylinders for drum brakes – another proof of our comprehensive expertise in matters concerning brakes.

Diaphragm cylinder

They act as a service brake and are characterised by small dimensions and low weight.

Spring-type cylinder

They act both as a service brake as well as an auxiliary and parking brake. They have a low weight compared with a diaphragm- piston cylinder.

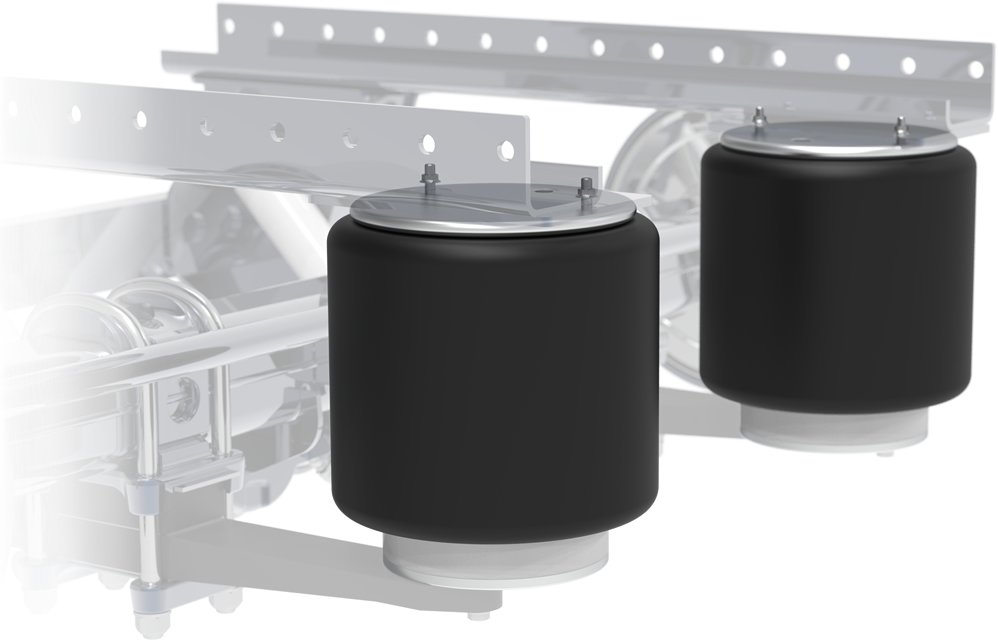

BPW Diaphragm cylinder

BPW Spring-type cylinder

BPW Diaphragm cylinder - Features and benefits

Constant high quality ensured by tests and permanent quality controls (FMEA, dimensional tests, release pressure tests, functional tests on the vehicle, vibration test, dirt tests, dynamic strength tests with more than 1 million braking cycles, hot and cold test (-40°C, 80°C), force output check

Improved sealing due to the innovative flanging technique

Optimum corrosion protection of housing components using different high-quality coating methods

Optimum corrosion protection of spring due to double coating

Inch and metric connections available

Easy to install due to compressed air connection extension

In drum brakes, there is no need for an external return spring between the slack adjuster and air cylinder bracket (precondition: mounting on BPW axles, round hole yoke end and lever length > 100 mm)

New ECE certificates and test reports are available on the BPW website

Hydraulic brake cylinder

The hydraulic brake cylinder is installed on the standard air cylinder bracket using an adapter. Hydraulic brake cylinders have a CEMAGREF approval in France.

BPW Hydraulic brake cylinder